Thinking about getting custom t-shirts made for your brand, event, or team? It's about so much more than just slapping a logo on a bit of fabric. A great custom tee turns a simple garment into a powerful statement, and this guide is here to walk you through exactly how to do it right here in Australia. We'll make sure your vision becomes a high-quality, wearable reality.

Bringing Your Custom T-Shirt Vision to Life

Ready to get that idea out of your head and onto a shirt? Let's get past the basics. Think of a custom tee as a canvas for your brand’s identity, a memento for an event, or just a cool way to express yourself. We'll cover the crucial decisions that make or break a great result, from choosing a fabric that actually feels good to wear to picking the printing method that makes your design truly stand out. Forget the guesswork; this is everything you need to know to manage your project with confidence.

Personalised apparel is booming. The Aussie custom t-shirt printing market was valued at USD 84.22 million and is on track to hit USD 133.93 million. That's some serious growth, and it shows just how much businesses and individuals are relying on custom gear to make a connection.

From Concept to Closet

Getting the perfect custom tee made involves a few key steps. Each one is a chance to sharpen your idea and ensure the final product hits the mark. It’s a bit like building a house – you need a solid plan before you start pouring the concrete.

Here’s the typical journey:

- Nail Down Your 'Why': Is this for a corporate event, a promotional giveaway, team uniforms, or merchandise to sell? The purpose dictates everything else.

- Choose Your Canvas: This means picking the right t-shirt style, fabric, and colour.

- Perfect the Print: You'll need to decide on the best printing technique for your design and budget.

- Prep Your Artwork: Getting your files print-ready from the get-go is the secret to avoiding delays and costly mistakes.

Once you get your head around these elements, you stop being just another customer and become an informed creator. You’ll be able to make smart decisions that save you time and money, all while getting a professional-looking result.

And once your amazing custom t-shirts are in hand, you might even think about selling them. Check out these expert tips for selling clothes online to help you turn your design into a success story.

Choosing the Perfect T-Shirt Canvas for Your Design

The perfect print starts with the right foundation. It’s easy to get caught up in the design, but the blank t-shirt you choose is just as important. Think of it like an artist’s canvas—its texture, material, and shape will completely change the final masterpiece.

A brilliant design printed on a cheap, scratchy shirt is always a letdown. On the other hand, the right garment can make even a simple logo look and feel premium. It’s not just about looks, either. You need to match the shirt to its job. Will it be a tough uniform worn every day, a lightweight tee for a charity fun run, or a budget-friendly giveaway for a trade show? Each one needs a different kind of canvas.

Getting to Know Your Fabrics

The material is the single biggest factor affecting how a t-shirt feels, how long it lasts, and how well it takes a print. While you’ll see all sorts of fancy blends out there, most tees boil down to a few key players.

- 100% Cotton: The old faithful. Everyone loves cotton because it’s soft, breathable, and feels great against the skin. It’s like a classic artist's canvas that soaks up ink beautifully, making it a fantastic choice for screen printing and DTG. The only downside? It can be prone to shrinking and wrinkling if you’re not careful.

- 100% Polyester: This is your go-to for anything active. Polyester is tough as nails, wicks moisture away to keep you dry, and resists shrinking and stretching. Its synthetic fibres are the perfect match for sublimation printing, which allows for those incredibly vibrant, all-over designs that literally become part of the fabric and never fade.

- Poly-Cotton Blends (e.g., 50/50): Why choose when you can have the best of both worlds? These blends give you the softness of cotton with the strength and wrinkle-resistance of polyester. They’re a super popular, reliable workhorse for almost any project.

- Tri-Blends (Cotton/Polyester/Rayon): This is the top-shelf stuff. Tri-blends are incredibly soft, lightweight, and have a stylish, slightly heathered look right off the bat. The rayon adds a beautiful drape and a silky feel, making them perfect for when you want to create retail-quality merch that people will want to wear again and again.

Seeing these fabrics in action can really help. Take a look through our clothing categories to get a feel for how these materials look across different styles, from basic tees to corporate polos.

Talking Weight and Fit

Beyond the fabric, the weight and cut of the shirt are crucial for getting the right vibe. You'll often see weight measured in GSM, which stands for Grams per Square Metre.

In simple terms, a higher GSM means a thicker, heavier t-shirt. Think durable and premium. A lower GSM means a lighter, more breathable garment, which is great for hot Aussie summers or as a cost-effective choice for big events.

For example, a heavyweight work tee might be 180-200+ GSM, giving it a sturdy, built-to-last feel. A lightweight fashion tee, however, could be around 130-150 GSM, offering a much softer, flowy drape.

The fit is the final piece of the puzzle. It’s what determines how the shirt actually sits on the body and the overall impression it gives off.

- Classic Fit: This is your standard, no-fuss t-shirt. It's got a boxier cut with plenty of room in the shoulders and body, making it a safe and comfy choice, especially for unisex orders where you need to fit everyone.

- Slim or Fashion Fit: A more modern, tailored cut that sits closer to the body. It’s narrower through the chest and waist for a sharper, more contemporary silhouette that works really well for brand merchandise.

- Unisex Fit: This is the happy medium. Designed to suit a wide range of body types, it lands somewhere between a classic and slim fit. It’s a versatile and smart choice when you're ordering for a large, mixed group of people.

By thinking through the fabric, weight, and fit, you’re no longer just "picking a shirt." You're strategically choosing the perfect canvas to make your design shine and ensure the final product is comfortable, durable, and looks fantastic.

Figuring Out the Best Printing Method for Your Project

So, you’ve picked out the perfect t-shirt to be your canvas. Now for the fun part: choosing the right “paint” and “brush.” The printing method you go with is a massive deal—it shapes the final look, the feel of the design on the fabric, and, of course, the cost of your printed t shirts custom order.

Think of it like this: each technique is a different tool in an artist’s kit. There's no single "best" method. It’s all about matching the right technology to what you want to achieve. A technique that’s perfect for a massive run of bold, simple logos would be a terrible fit for a small batch of tees with a photorealistic design. Getting this right is the key to making sure your idea jumps from the screen to the fabric just the way you imagined.

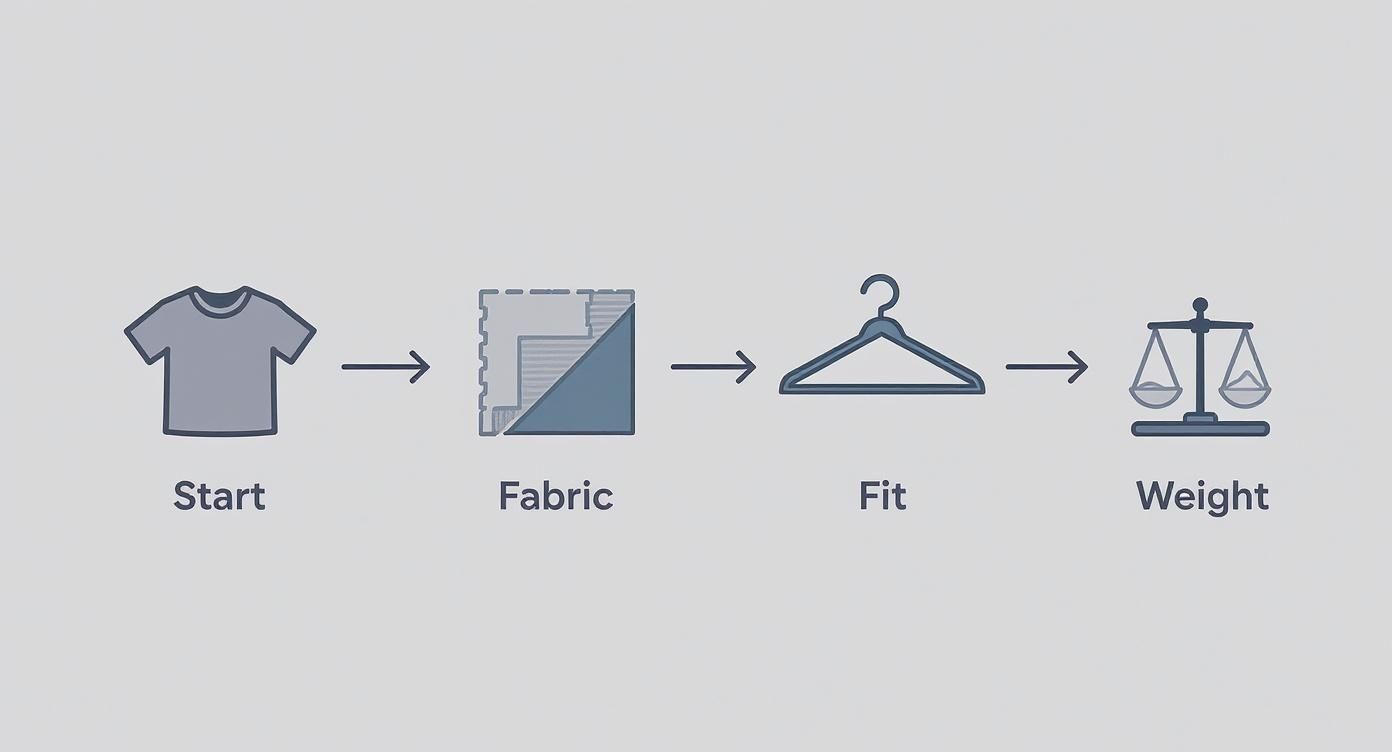

This flowchart gives you a bird's-eye view of the first few choices you'll make, which will point you toward the right printing method.

As you can see, fundamental decisions about the shirt itself—like its material and the fit you're after—are the first steps to a great final product.

Screen Printing: The Stencil Powerhouse

At its core, screen printing is a souped-up version of stencilling. A fine mesh screen is used to push a thick layer of ink onto the t-shirt, one colour at a time. This means every single colour in your design needs its own dedicated screen, which takes a bit of work to set up.

That setup is precisely why screen printing is the king of big orders. The initial cost gets spread out over hundreds of shirts, dropping the price-per-tee right down. It's the undisputed champ for bulk orders with simple, punchy graphics—think large corporate events, school uniforms, or band merchandise.

- Best For: Large quantities (usually 50+), designs with 1-4 solid colours, and getting that super vibrant, durable print.

- Analogy: It’s like using a stencil to paint a wall. Perfect for repeating the same design over and over with bold, consistent results that really pop.

The ink sits right on top of the fabric, creating a slightly raised feel that you can touch. It’s incredibly durable, making it a fantastic choice for workwear or team uniforms that will see a lot of action and a lot of washing.

Direct-to-Garment (DTG): The Fabric Inkjet

Direct-to-Garment, or DTG, is pretty much what it sounds like. It works just like a high-end inkjet printer at home, but instead of printing on paper, it prints straight onto the fabric. This method is a game-changer for creating incredibly detailed, full-colour images with smooth gradients and photorealistic vibes.

Because there are no screens to make, the setup is almost zero. This makes it perfect for small orders or even one-off prints. If your design has a dozen colours or intricate shading, DTG is your best friend. It can reproduce complex art without losing any of the detail.

DTG printing is the perfect solution for businesses wanting to test a design without committing to a massive inventory. It gives you total creative freedom and is ideal for high-detail, small-batch merchandise.

One thing to keep in mind, though: DTG uses water-based ink that soaks into the fibres. This means it works best on 100% cotton garments. The end result is a print that feels incredibly soft and breathable, with no texture at all—it’s just part of the shirt.

Heat Transfer: The Versatile Press

Heat transfer is a two-step process: your design is first printed onto special transfer paper, then a heat press is used to bond it to the t-shirt. It’s an incredibly versatile method that produces crisp, clean logos and text with super-sharp edges.

You’ve got a couple of options here, like vinyl or digital transfers. Vinyl is brilliant for simple, bold shapes like names and numbers on the back of sports jerseys, giving you a smooth, slightly rubbery finish. Digital transfers, on the other hand, can handle full-colour designs, making them a great alternative to DTG for small runs on different fabric types, including polyester.

To get a better feel for what’s possible, you can explore the various custom printing options out there to see which one lines up with your art and fabric choice.

Dye Sublimation: The All-Over Artist

Dye sublimation is where science gets really creative. The design is printed with special inks onto paper. When heat and pressure are applied, the inks turn into a gas and permanently fuse with the polyester fibres of the shirt. The ink literally becomes one with the fabric.

This means the print has zero feel to it and will never crack, peel, or fade. Ever. Sublimation lets you create mind-blowing, edge-to-edge, all-over prints that are incredibly vibrant. The one major catch? It only works on light-coloured, 100% polyester garments. This makes it the ultimate choice for custom sportswear, activewear, and any design that needs to cover the entire t-shirt in seamless, vivid colour.

Printing Method Comparison Guide

To make the choice a bit easier, here’s a side-by-side look at the most popular printing methods. Use this guide to quickly see which option aligns best with your design, quantity, and budget.

| Method | Best For | Fabric Suitability | Pros | Cons |

|---|---|---|---|---|

| Screen Printing | Bulk orders (50+), simple designs (1-4 colours), vibrant & durable results | Cotton, blends, polyester | Very cost-effective in bulk, extremely durable, vibrant colours | Not suitable for small orders, limited colour complexity |

| DTG | Small runs, photorealistic images, full-colour designs, soft feel | Primarily 100% cotton | No minimum order, excellent detail & colour range, soft finish | Not cost-effective for large runs, best on light-coloured fabrics |

| Heat Transfer | Names/numbers, small logos, various fabric types (including polyester) | Cotton, polyester, blends | Versatile, works on many fabrics, good for small orders, sharp edges | Can feel thick on the shirt, may crack over time with poor care |

| Dye Sublimation | All-over prints, sportswear, full-colour designs on polyester | 100% polyester (light-coloured) | Permanent (no cracking/fading), breathable, vibrant edge-to-edge prints | Only works on polyester, limited to light-coloured garments |

Ultimately, the best printing method comes down to your specific needs. A screen print that’s perfect for a 500-shirt event giveaway won’t be the right choice for a five-shirt order for your startup team, where DTG or a heat transfer would make more sense.

Preparing Your Artwork for a Flawless Print

A brilliant print is impossible without quality artwork. This is the stage where a great idea can either soar or stumble, and getting it right from the start saves you from costly reprints and delays. The good news is you don’t need to be a graphic designer to understand the essentials.

This section is your straightforward guide to preparing your files, minus the confusing technical jargon. By understanding a few key concepts, you can supply perfect files or communicate your needs clearly to your printing partner. This ensures your printed t shirts custom order comes out looking sharp, professional, and exactly as you envisioned.

Vector vs Raster: The Recipe and the Photograph

The most important concept to wrap your head around is the difference between vector and raster files. Honestly, getting this right is fundamental to achieving a crisp, clean print that looks great at any size.

Here's a simple way to think about it:

A vector file is like a mathematical recipe. It uses lines and curves defined by equations, not pixels. This means you can scale it up to the size of a billboard or shrink it down to fit on a pen, and it will always be perfectly sharp and clear.

On the other hand, a raster file is like a photograph. It’s made up of a fixed grid of tiny squares called pixels. Common raster file types include JPEGs, PNGs, and GIFs.

While they're great for photos, they have one major limitation. If you try to enlarge a raster image too much, it becomes blurry and "pixelated" as the individual squares become visible. For professional printing, vector is almost always the preferred format for logos and graphics.

- Vector File Types: AI (Adobe Illustrator), EPS, SVG, and sometimes PDF.

- Raster File Types: JPG, PNG, GIF, TIFF.

Resolution and Why 300 DPI Matters

Sometimes you have to use a raster file, like for a photograph on a shirt. When you do, its resolution becomes critical. Resolution is measured in DPI (Dots Per Inch), which tells you how many pixels are packed into one inch of the image.

For screen viewing, 72 DPI is standard. But for printing, the industry benchmark is 300 DPI. An image at this resolution has enough pixel density to produce a sharp, high-quality print without any blurriness. Submitting a low-resolution file is one of the most common reasons for a disappointing print job. For achieving sharp and professional results, understanding 300 DPI resolution for printing is a crucial step.

The demand for high-quality finished products is a key driver in the broader Australian apparel market. The total market value for t-shirts in Australia recently hit $889 million, a significant 9.7% increase from the previous year, reflecting a strong consumer appetite for well-made garments.

Essential Artwork Tips for Success

Beyond file types and resolution, a few other best practices will ensure your artwork is print-ready. Following these simple steps can prevent common headaches like incorrect colours or unexpected white boxes appearing on your final shirt.

- Always Use a Transparent Background: Unless a coloured box is part of your design, save your file with a transparent background. A PNG file is perfect for this. This prevents a white or black box from being printed around your logo on a coloured tee.

- Outline Your Fonts: If your design includes text, the fonts must be converted to outlines or embedded in the file. This turns the text into a vector shape, ensuring it prints correctly even if the printer doesn't have that specific font installed on their system.

- Specify Your Colours: If your brand uses specific colours, provide the Pantone (PMS) colour codes. This helps the printer match your brand colours as closely as possible, ensuring consistency across all your merchandise.

For a deeper dive into preparing your files, you can check out our guide on artwork submission tips for beginners. It offers more detail to help you feel completely confident when sending your designs to print.

Breaking Down the Costs and Timelines

Figuring out the cost and logistics for custom printed t-shirts in Australia is a lot simpler once you know what's behind the price tag. I always tell my clients to think of it like ordering a pizza: you've got your base price, but the final cost really depends on the size, how many toppings you add, and how fast you need it. The same idea applies here, and understanding it is key to budgeting properly and avoiding any last-minute surprises.

The price you pay per shirt isn't just a number pulled out of thin air. It’s a careful calculation based on a few key things: the t-shirt itself, the printing method you go with, how complex your design is, and, of course, how many you're ordering. A premium, heavy-duty cotton tee is naturally going to cost more than a basic promotional one, just like a vibrant, multi-colour screen print will be priced differently from a simple one-colour logo.

This is why getting a clear, itemised quote is so important. Demand for custom gear is always growing, and the Aussie market is pretty dynamic. In fact, one report noted an 11.93% jump in imports for custom t-shirt printing, which just shows how much we rely on different materials to get the job done right. If you're interested in the nitty-gritty of market trends, you can explore the full research on the Australian custom t-shirt printing market outlook.

Key Factors That Shape Your Quote

To nail down a realistic budget, you need to know exactly what goes into the final price. Every little detail plays a part, and tweaking even one of them can make a big difference to your total spend.

Here’s a look at the main things we consider when putting together your quote:

- The T-Shirt Itself: The brand, style, fabric, and colour you choose are the starting point.

- Printing Method: Screen printing, DTG, and heat transfer all have different setup requirements and material costs.

- Number of Colours: With screen printing, every single colour in your design needs its own screen. More colours mean more screens and more setup time.

- Print Locations: A print on the front is standard. But if you want to add something to the back, sleeves, or even a custom tag, that will add to the cost.

- Order Quantity: This is the big one. The more shirts you order, the cheaper each one becomes.

The Power of Bulk Orders and Minimums

One of the easiest ways to bring down your cost-per-shirt is simply to order more. It’s a classic case of economies of scale, and it’s especially true for screen printing. The initial setup—burning the screens, mixing the inks—is the most time-consuming part of the job. Once that's done, printing 100 shirts doesn't take much longer than printing 25.

By ordering in bulk, you spread that fixed setup cost across a larger number of garments, dramatically lowering the price of each individual tee. This is why a 100-shirt order might have a significantly lower per-item cost than a 25-shirt order with the exact same design.

Most printers, including us, have a Minimum Order Quantity (MOQ). This is just the smallest order we can run to make the setup costs worthwhile. If you only need a handful of tees, a method like DTG, which has almost no setup, is a much better fit. Want to see how these factors affect your price in real-time? Play around with our instant print quote tool to see the numbers change as you adjust your order.

Production Timelines, Proofs, and Getting It Right

Finally, let's talk about timing. A standard production run usually takes about 7-14 business days from the moment you sign off on the final artwork. This gives us enough time to get the t-shirts from our supplier, set up the job, run the print, and do our quality checks.

Need your shirts in a hurry? We get it. Most printers can offer a rush service for an extra fee, which can often slice the production time in half. The key is to let us know about your deadline right from the get-go.

Before a single shirt hits the press, you will always get a digital proof or mock-up sent to your email. This is your last chance to triple-check everything—spelling, colours, logo size, and placement. Look at it carefully, because once you give the thumbs-up, the machines start rolling

Your Final Pre-Order Checklist

Placing a big order for custom t-shirts can feel a little nerve-wracking. To make sure everything goes off without a hitch, it’s smart to run through a quick final check before you hit ‘go’. This simple list brings together everything we’ve talked about, helping you catch any small oversights before they become big headaches.

Think of it as your last line of defence against common mistakes. A few minutes now will save you a world of stress later, ensuring the final t-shirts you receive are exactly what you envisioned.

Your 5-Point Pre-Order Check

Before you lock anything in, quickly ask yourself these five questions. It’s the best way to make sure you and your printer are completely on the same page.

- Is the Purpose Clear? Have you nailed down exactly who these t-shirts are for and what they need to do? A cheap-and-cheerful giveaway tee for a one-day event is a totally different beast to a durable, premium uniform for your staff.

- Is the Artwork Actually Ready? Is your design file a proper vector format (like AI, EPS, or SVG)? If it’s a raster file, is it at least 300 DPI? Make sure you’ve outlined all your fonts and that the background is transparent.

- Are the T-Shirts Confirmed? Have you picked the final style, fabric, and colour? Crucially, do you have the exact size breakdown you need? Getting the sizes wrong is probably the most common (and most avoidable) mistake we see.

- Is the Print Method Right? Based on your design complexity, quantity, and t-shirt choice, have you picked the best decoration method? Screen printing is great for bulk orders, but DTG might be the only way to get that full-colour photo printed perfectly.

- Have You Checked the Proof and Deadline? Look over the digital proof very carefully. Check for spelling mistakes, check the logo placement, and check the colours. Finally, have you made your delivery deadline crystal clear to your supplier?

Once you can say "yes" to all of these, you're in a fantastic position. You haven’t just hoped for a good outcome; you've planned for it.

This isn't just a list to avoid problems—it's about making sure you get exactly what you're paying for. It puts you in the driver's seat and ensures your investment in custom apparel really works for you.

With these questions answered, you’re ready to get started. When you're ready to go, you can order promotional products with total confidence, knowing you’ve got all your ducks in a row.

Got Questions? We’ve Got Answers.

Even after you've nailed down the design and picked the perfect tee, a few last-minute questions always seem to pop up. Don't worry, it's completely normal. Let's tackle some of the most common queries we hear from our clients across Australia so you can place your order with total peace of mind.

Think of this as your final pre-flight check before your custom t-shirts take off.

Can I mix and match different shirt colours in my order?

Absolutely. This is one of the most common things people ask, and the answer is almost always yes.

As long as the artwork itself – the design, the size, and the ink colours – stays exactly the same, you can print it across a whole range of different t-shirt colours and even styles. For instance, you could easily split a 50-shirt order into 25 classic black tees and 25 slim-fit navy ones. It's a great way to give your team or event attendees some variety without the hassle of multiple small orders. Just give your printer a heads-up first to confirm.

What’s the deal with reordering more shirts later on?

Need a top-up? Reordering is usually a breeze, especially if you stick with the same printer. They'll have all your artwork and job details saved, which makes setting up a repeat run quick and painless.

Here's a pro tip though: if your first batch was screen printed, the screens used for your design would have been cleaned and reused for other jobs. That means a reorder requires a whole new setup, and the original minimum order quantity will likely apply again. It’s often cheaper in the long run to order a few spares upfront than to get caught needing a small, expensive reorder down the track.

How do I make sure the colours turn out right?

Getting colours spot-on is part art, part science. The vibrant red you see on your computer screen can look totally different once it's ink on a cotton tee.

The absolute best way to guarantee colour accuracy is to give your printer the Pantone Matching System (PMS) codes for your brand colours. If you don't have these, a good printer will help you find the closest possible ink match from their swatches. For projects where the colour has to be perfect, always ask for a physical print sample before they start the full run. It’s the only surefire way to know you’ll love the final result.

Ready to create custom apparel that gets your brand noticed? The expert team at Simply Merchandise is here to help you every step of the way, from design to delivery. Explore our range and get a free quote today!