Embroidered polo tops are a classic for a reason. They hit that sweet spot between smart and comfortable, making them a go-to for business uniforms and promotional gear. When done right, they offer a durable, high-quality finish that really lifts your company's image, turning a simple garment into a lasting investment.

Why Embroidered Polos Are a Smart Investment

Picking the right apparel for your team or event isn’t just about ticking a box; it's a real branding opportunity. Embroidered polo tops are a top-tier choice because they deliver an excellent return on investment. How? Through durability, professionalism, and consistent brand exposure.

Unlike printed logos that can fade, crack, or peel over time, embroidery gives you a textured, premium finish that holds up wash after wash. It immediately signals quality and a genuine attention to detail.

This lasting quality is what makes them such a reliable tool for creating a unified team look. Picture your sales team at a major trade show – sharp, professional, and instantly recognisable in their matching polos. Or think about volunteers at a community event, projecting a coordinated and trustworthy image. In every case, the apparel is doing more than just clothing them; it’s building a sense of belonging and making your brand memorable.

Durability Meets Professionalism

One of the biggest wins with embroidery is its sheer resilience. Here in the Australian promotional merchandise space, this durability is a massive selling point for businesses. Recent trends show that 65% of small and medium Australian businesses are choosing embroidered polos for their staff uniforms. A key reason is that a well-stitched logo can easily last up to 50 washes without losing its colour or shape.

That kind of longevity means your investment keeps working for you long after the initial purchase.

When you invest in high-quality embroidered apparel, you’re not just buying uniforms. You’re creating walking billboards that maintain a polished, professional look for years, strengthening your brand recognition every time they’re worn.

A Versatile Branding Tool

The usefulness of an embroidered polo goes well beyond the standard staff uniform. They are a genuinely flexible asset for all sorts of business activities.

- Corporate Events and Trade Shows: Nothing creates a cohesive, professional presence quite like a uniformed team. It makes your people easy to spot and approach.

- Client Gifting: An embroidered polo is a practical, high-value gift that keeps your brand top-of-mind every time your client wears it.

- Team Building Activities: Foster a sense of unity and team pride during off-site events, internal competitions, or casual Fridays.

At the end of the day, these garments are a core piece of a much bigger branding puzzle. They work hand-in-hand with other promotional products to build a consistent and recognisable brand identity that people trust.

Choosing the Right Fabric and Style for Your Team

Before you even think about logos and embroidery, the foundation of a great company polo is its fabric and fit. These two things will make or break how the shirt feels, performs, and looks, which directly affects your team's comfort and how they represent your brand. It’s less about what looks good on a mannequin and more about what works for your people in their specific roles.

Think about it: a team working long shifts in an air-conditioned office will appreciate softness and a classic feel. On the other hand, an outdoor events crew needs something that breathes, wicks away sweat, and stands up to the Aussie sun. Each job calls for a different material to make sure your team is comfortable and looking sharp all day long.

Decoding Polo Fabrics

The material you choose is probably the biggest factor in both comfort and longevity. Most polos fall into one of three main categories, each with its own set of pros and cons.

Here’s a quick guide to help you decide.

Polo Fabric Comparison Guide

| Fabric Type | Key Benefits | Best For | Care Considerations |

|---|---|---|---|

| 100% Cotton | Soft, breathable, classic premium feel. | Office staff, corporate events, low-activity roles. | Slower to dry, can wrinkle, may shrink if not cared for properly. |

| 100% Polyester | Durable, moisture-wicking, wrinkle & fade resistant. | Sports teams, outdoor workers, physically demanding jobs. | Can sometimes retain odours if not washed correctly. |

| Poly-Cotton Blend | Combines cotton's softness with polyester's durability. | The all-rounder for most business uniforms, from retail to trades. | Offers a good balance, but check the specific blend percentage for desired traits. |

So, a logistics company, for example, would be smart to choose a poly-cotton blend. Their drivers get a shirt that’s tough enough for the daily grind but still comfortable and professional-looking when they’re meeting clients. It’s a workhorse fabric that ticks all the boxes.

Finding the Perfect Style and Fit

Once you’ve nailed the fabric, the next piece of the puzzle is the style and fit. A consistent, professional look across your team comes down to getting this right. Thankfully, we’ve moved past the days of the one-size-fits-all, boxy polo.

A crucial first step is choosing between men's, women's, and unisex cuts. Women’s styles are specifically tailored to provide a much more flattering silhouette, which makes a world of difference for comfort and confidence. Offering gender-specific fits is a simple way to show you’ve considered everyone on the team.

You should also think about whether your industry requires specialised styles. It's often worth exploring broader clothing categories to see what other options are out there.

- Long-Sleeve Polos: Perfect for cooler weather or for a slightly more formal, up-market look. They’re a great choice for front-desk staff or sales reps visiting corporate clients.

- Hi-Vis Polos: An absolute must-have for anyone in construction, logistics, or event management where safety is paramount. These aren't just bright colours; they are designed to meet strict Australian safety standards for visibility.

Getting Your Embroidery Customisation Just Right

Embroidery is what takes a simple polo shirt and turns it into a powerful statement for your brand. To get that sharp, professional finish that makes your team look the part, you need to nail the customisation process. It's about much more than just sticking a logo on a shirt; it’s about choosing the right technique, placement, and colours to make your design truly pop.

First things first, let's talk about the different embroidery methods available. Each technique offers a unique look and feel, so picking the right one depends entirely on your branding goals.

Choosing Your Embroidery Technique

The two most common styles you'll come across are the classic flat stitch and the more striking 3D puff embroidery. While both deliver great results, they serve very different purposes.

- Standard Flat Stitch: This is the workhorse for most corporate logos, and for good reason. It creates a clean, classic, and detailed finish that sits flat against the fabric. It’s perfect for intricate designs, text, and any logo where clarity is absolutely essential.

- 3D Puff Embroidery: This technique uses a foam underlay to physically raise the stitches, giving the design a tactile, three-dimensional effect. It’s fantastic for simple, bold shapes or single letters—think of the logos on sporting team caps. It isn't the right choice for fine text or complex details, as they tend to get lost in the puff.

For most business applications, the standard flat stitch is going to give you that polished, professional look you’re after for your embroidered polo tops. It’s versatile, incredibly durable, and ensures your logo is represented crisply and clearly.

Strategic Logo Placement

Where you put your logo is just as important as the design itself. The position can completely change the tone of the garment, shifting it from subtle and corporate to bold and promotional.

The left chest is the traditional, and by far the most popular, choice. It’s highly visible during face-to-face conversations and handshakes, which is why it has become the industry standard for professional uniforms.

That said, other placements can be incredibly effective:

- Sleeve Placement: A logo on the left or right sleeve offers a more subtle, modern feel. It’s a great spot for secondary branding or for a sophisticated corporate look where a chest logo might feel too overt.

- Back Yoke: Placing a logo just below the collar on the back is perfect for event staff or teams where being seen from behind is important. It provides a large, clean canvas for your brand.

Think about how the polos will be used. For a sales team, a classic left-chest logo reinforces your brand during meetings. For a large-scale event, a prominent logo on the back helps attendees easily identify your staff from any direction.

Preparing Your Artwork for Embroidery

To get the best possible result, your logo needs to be 'digitised'. This is the process of converting your digital artwork file into a stitch-by-stitch map that the embroidery machine can actually read. You can get a deeper look into our in-house custom embroidery services to see the full process in action.

To ensure a smooth transition from your screen to the final stitch, keep these tips in mind:

- Simplify the Details: Extremely fine lines, tiny text, and complex colour gradients don't translate well to thread. Simplify your design where you can for a much cleaner outcome.

- Go for Contrast: Pick thread colours that stand out against your polo fabric. A navy thread on a navy polo will just disappear, so opt for a lighter or brighter colour to make sure your logo is visible.

This attention to detail is precisely why embroidery is so highly valued. In fact, Australian suppliers report that custom embroidered polos make up 45% of all branded apparel sales. Embroidery is also preferred by 82% of clients over screen printing for logos under 10,000 stitches, thanks to its superior definition and professional finish. You can discover more insights about these local apparel trends at Brand Republic.

Getting Your Artwork and Pricing Sorted

Getting the technical side of things right from the get-go is the secret to a stress-free order and a polo that looks fantastic. Once you understand what's needed for your artwork and what actually drives the cost, you can budget properly and avoid any nasty surprises down the track. It’s all about making sure your digital design translates perfectly into physical stitches.

The single most important thing for sharp, clean embroidery? Your artwork file. For a professional finish, a vector file is an absolute must-have. We're talking about files ending in .AI, .EPS, or sometimes a high-quality .PDF – the kind you get from a graphic designer using a program like Adobe Illustrator.

Unlike a standard image file (like a .JPG or .PNG) which is just a grid of pixels, a vector file is built from mathematical lines and curves. This means you can blow it up to the size of a billboard or shrink it to fit on a pen, and it will never get blurry or lose quality. This is crucial for the digitising process, where your logo is meticulously converted into a stitch-by-stitch map for the embroidery machine.

Why Stitch Count is King When it Comes to Cost

The main thing that determines your embroidery cost is the stitch count. It's simply the total number of stitches needed to bring your logo to life on the fabric. A simple text-based logo might only take 5,000 stitches, but a detailed company crest with lots of solid-filled areas could easily jump to over 20,000 stitches.

More stitches mean more thread and more time on the machine, which naturally translates to a higher price per polo. When you send over your vector file, the first step for any supplier is to digitise it to get this exact stitch count, which becomes the foundation of your quote.

Your stitch count is the single biggest factor in the final price of your embroidered polos. A dense, complex logo will always cost more to produce than a simple, clean one, even if they use the same number of colours.

A couple of other things can influence the price too:

- Number of Colours: While not nearly as important as the stitch count, using lots of different thread colours can sometimes nudge the price up slightly due to the extra setup time on the machine.

- Order Quantity: This is where you can really see the savings. Ordering in bulk drastically drops the price you pay for each polo.

A Quick Pricing Example

Let's break it down with a real-world scenario. Say you're ordering polos for two different needs.

- The Small Team Order: You need 20 polos for the crew at your local office. All the initial setup costs are spread across just 20 garments, so the price per polo will be higher.

- The Big Conference Order: You need 200 polos for a national event. Those exact same setup costs are now divided by 200, which brings the individual price right down.

You could easily see the price per polo for the 200-unit order being 20-30% lower than the 20-unit one. This just goes to show how planning ahead and ordering for the whole year at once can lead to some serious savings. If you're reselling these or just want to get a better handle on the numbers, learning how to effectively price custom shirts is a really useful skill to have for your own budgeting.

For a deeper dive into getting your files ready, take a look at these handy artwork submission tips for beginners. It’ll help make sure your project gets off to the perfect start.

Nailing the Final Details and Sidestepping Common Pitfalls

You’ve done the hard work of choosing your polo style, fabric, and embroidery. Now comes the crucial final stage: locking in the details and placing your order. This is where precision matters most. Getting these last steps right is the difference between a smooth process and a project riddled with costly delays and disappointment.

One of the easiest mistakes to make, and one I see all the time, is messing up the size breakdown. Don't guess. A "Medium" from one supplier can be wildly different from another, and nothing undermines a uniform program faster than ill-fitting shirts. The first thing you should do is ask for the specific size chart for the exact polo you've chosen.

Even better, ask if a sizing kit is available. This is a game-changer. Your supplier sends a set of blank polos in every size, allowing your team to physically try them on. It completely removes the guesswork and guarantees everyone gets a fit they’re happy with.

The Power of a Pre-Production Sample

Before you commit to the full order, always, always request a pre-production sample. I can't stress this enough. This is a single, finished polo with your actual embroidery on it. It’s your final chance to see, touch, and approve the real thing before you have 200 of them on your doorstep.

When your sample arrives, put on your quality control hat and inspect it closely:

- Stitching Integrity: Is the embroidery clean and tight? Check for any loose threads or puckering where the stitches pull on the fabric.

- Colour Matching: How do the thread colours look in real life compared to your brand guide? Is the fabric colour what you expected?

- Placement and Proportions: Is the logo positioned exactly where you wanted it? Is it straight and scaled correctly on the garment?

Finding a colour issue or a crooked logo on one sample is an easy fix. Finding it on a full delivery is a nightmare. This single step is your most important quality assurance check.

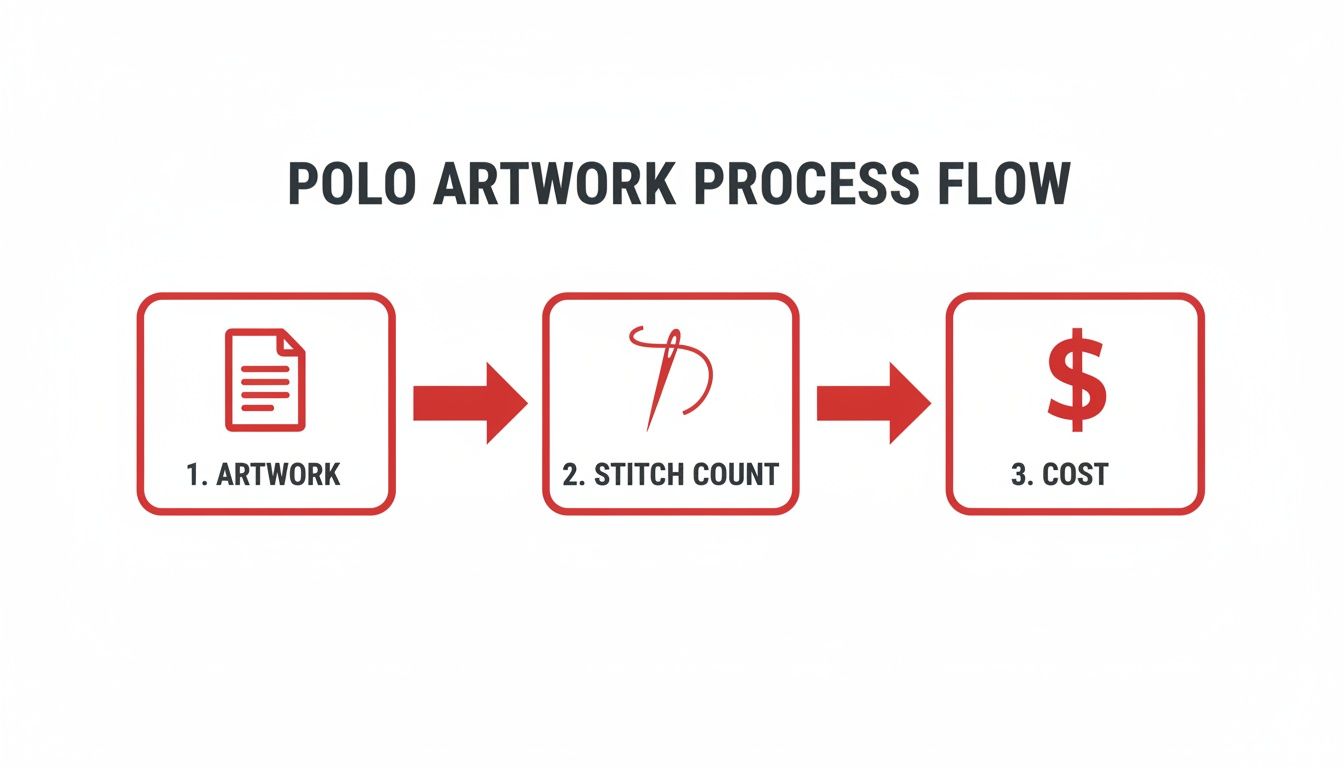

This diagram breaks down how your design choice directly impacts the stitch count, which in turn determines the final price.

As you can see, a more detailed logo means a higher stitch count, and that’s the biggest factor in your embroidery cost.

Getting Your Timing Right

Finally, let’s talk about timelines. Be realistic. A typical order takes about two to three weeks to complete, but that clock only starts after you’ve signed off on the artwork proof and the physical sample. This window covers everything from getting the blank polos in, setting up the embroidery machines, the production run itself, and shipping.

If you’re ordering for a specific event, tell your supplier about your deadline right from the very first conversation. Rush services are often available for a fee, but they aren't a given, especially during busy seasons.

My advice? Build a buffer of at least one extra week into your schedule. It’s a simple move that provides a huge amount of peace of mind, protecting you from unforeseen shipping hiccups or production delays.

Ready to put this all into action? You can request a quote and outline your needs to get a clear production timeline and expert advice for your project.

Got Questions? We've Got Answers

Even the most organised buyer will have a few questions pop up when it comes to custom apparel. It's only natural. So, I've put together some quick, straightforward answers to the most common queries we get from businesses ordering embroidered polos. Sorting these details out early makes the whole process a lot smoother.

"How Do I Make Sure My Brand Colours Are Perfect?"

Getting your colours right is everything – it's the difference between looking professional and looking... well, a bit off. The gold standard for colour matching is to give us your Pantone (PMS) colour codes. This is a universal system that lets our embroidery team pull the exact thread to match your brand guidelines. No guesswork involved.

Don't have PMS codes? No stress. A high-resolution digital file of your logo is the next best thing. We can do a very close visual match. Either way, you'll always get a digital proof before we start stitching. This mock-up shows the thread colours on your chosen polo, so you can give the final thumbs-up.

"What's a Stitch Count and Why Does It Change the Price?"

Think of the stitch count as the DNA of your embroidered logo – it’s the total number of stitches needed to bring it to life. This is the single biggest factor that determines your final cost. For instance, a simple text-based logo might only take 5,000 stitches. In contrast, a detailed crest with solid blocks of colour could easily jump to 20,000 stitches or more.

The reason it affects the price is simple: more stitches mean more thread and, crucially, more time on the machine. The first thing that happens when you send your artwork is a process called digitising. This is where we convert your design into a stitch-by-stitch map, which gives us the exact count and forms the basis of your quote.

Here's a handy rule of thumb: The denser and more intricate your design, the higher the stitch count and the higher the cost. Sometimes, simplifying your logo slightly can lead to big savings without sacrificing that premium look.

"Can We Get Different Names on Each Polo?"

Yep, you absolutely can. This is what we call personalisation, and it's a brilliant touch for making team uniforms look sharp and professional. We can add individual names or roles, which usually sit on the right chest (opposite the logo) or sometimes on one of the sleeves.

There’s typically a small extra charge for each garment to cover the setup for each unique name. The process on your end is easy – just send over a spreadsheet with two columns: the name you want and the corresponding polo size. Simple as that.

"How Do I Look After Our New Polos?"

A little bit of care goes a long way in keeping your embroidered polos looking crisp for years. To protect the fabric and the beautiful stitching, we always recommend these simple habits.

- Turn it Inside Out: Before you wash it, flip the polo inside out. This protects the embroidery from getting snagged or rubbed by other clothes in the wash.

- Keep it Cool: A gentle cycle with cold or lukewarm water is best. It helps prevent shrinking and keeps the thread colours looking bright and new.

- No Harsh Stuff: Stay away from chlorine bleach. It's tough on the fabric and can make the embroidery threads fade or become brittle.

- Go Low on Heat: You can tumble dry on a low setting, but for best results, hang your polos to air dry. It puts less stress on the stitches.

- Iron Smart: If you need to iron, never put the hot iron directly on the embroidery. Turn the polo inside out and iron from the back, or just place a tea towel over the logo first.

Ready to create high-quality embroidered polo tops that make your team stand out? The experts at Simply Merchandise are here to guide you through every step, from artwork to delivery.

Explore our custom polo options and get your free quote today at simplymerchandise.com.au